Ambimization®: Cleaning up the manufacturing industry

What do automotive, coatings and composite manufacturers have in common? Typically, they clean manufacturing equipment with toxic solvents and heated detergents that are dangerous to staff, harmful to the environment and often aren’t very effective.

Industrial coatings are, by nature of their protective purpose, resilient and notoriously difficult to clean from manufacturing vessels and infrastructure. Consequently, the industry has relied on traditional solvents which are extremely high in VOCs, a leading cause of ground level smog and the pollution of our planet.

Similarly, automotive manufacturers deploy heated detergents and solvent-based cleaning processes which are energy consuming, high in VOCs, require ATEX zoning, expose employees to unnecessary risk and create hazardous waste.

Manufacturing sites that use solvents and heated detergents for cleaning produce thousands of liters of solvent waste per year and are under increasing pressure to create safer and more sustainable processes.

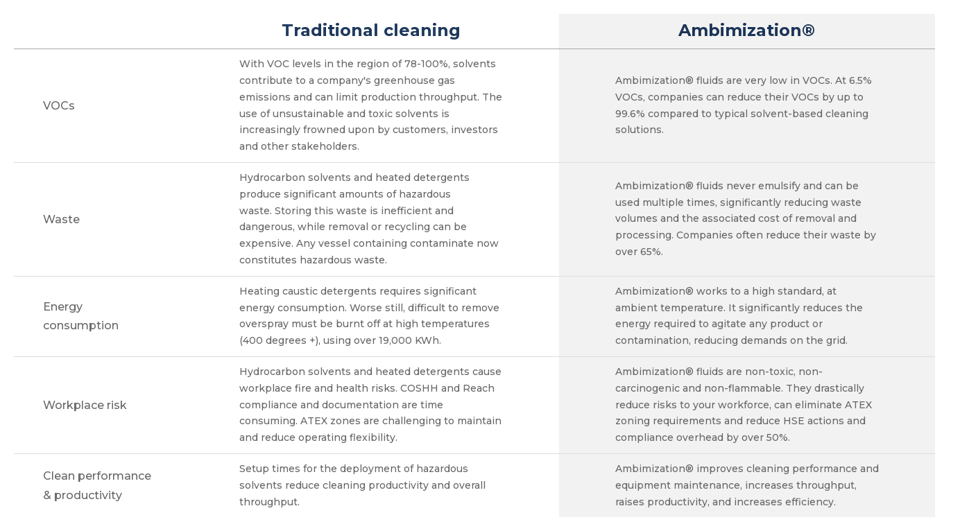

Ambimization® vs traditional cleaning

Traditional solvents and heated detergents clean by emulsifying a product or contaminant into the body the solution. They can often struggle with tough cleaning challenges and can only be used for a short period of time before needing disposal. This creates a significant amount of waste which is both hazardous and expensive to remove. In addition, heated detergents use large amounts of energy to ensure they are heated to the right operating temperature.

At Terrafend, we relentlessly innovate to find sustainable, high-performance replacements for solvents that place people and our planet at risk. Ambimization®, our patented cleaning technology, is reinventing cleaning processes and empowering manufacturers to meet sustainability requirements while increasing productivity and safety. Ambimization® fluids are non-toxic, non-flammable, non-carcinogenic and contain as little as 6.5% VOCs.

Ambimization® delivers improved cleaning performance compared to traditional cleaning methods and solvents. Our fluids are designed to penetrate through the surface of a contaminant right back to the substrate where they can change the surface tension where the two-meet, enabling the contaminant to literally fall off the surface of the part. When the contaminant reaches the solution itself, it will either float for surface or sink to the bottom giving you an area in the middle that you can recycle and reuse multiple times.

Terrafend’s patented Ambimization® process is about keeping products and resources in the best working condition for as long as possible and moving away from a model where hazardous waste is created and disposed of, towards one where clean and sustainable fluids can be used repeatedly.

Safeguarding employees & protecting the planet

At a time when manufacturers are trying to reduce waste, solvent-based cleaning produces significant volumes of emulsified waste which is harmful to remove and process. And when manufacturing equipment cannot be properly cleaned for reuse, it is disposed to landfill.

Terrafend is delivering a material sustainability impact, while reducing workplace risks.

- An automotive OEM reduces spray gun cleaning waste by 80%

- A global paint manufacturer eliminates 20% of total site VOCs

- An automotive OEM saves 19,000 kWh in gas consumption for grid cleaning

- A global paint manufacturer to reduces HSE open list by 50%

.png?width=2240&height=1260&name=Ambimization-CTA%20(1a).png)