Terrafend’s machine range brings together over a decade of innovation in manual wash tanks, pressure wash systems, ultrasonic tanks, soak tanks, and vessel cleaning platforms. Built entirely from 304 stainless steel, every system is designed to maximise the performance of our advanced aqueous chemistries — delivering powerful results while remaining rugged enough for the harshest industrial environments and intuitive enough to make cleaning simple and efficient for operators.

Proudly designed and manufactured in the UK, our machines are trusted by global OEMs, coatings manufacturers, engineering firms, and industrial leaders worldwide. Built to last and engineered to perform, they combine stainless steel durability, user-friendly design, and cutting-edge chemistry to transform the way industry approaches cleaning.

The Typhoon 450 is a compact manual wash tank designed for smaller parts and workshops. Built for durability and ease of use, it delivers powerful cleaning with Terrafend fluids, replacing traditional solvent systems with a safer, smarter alternative.

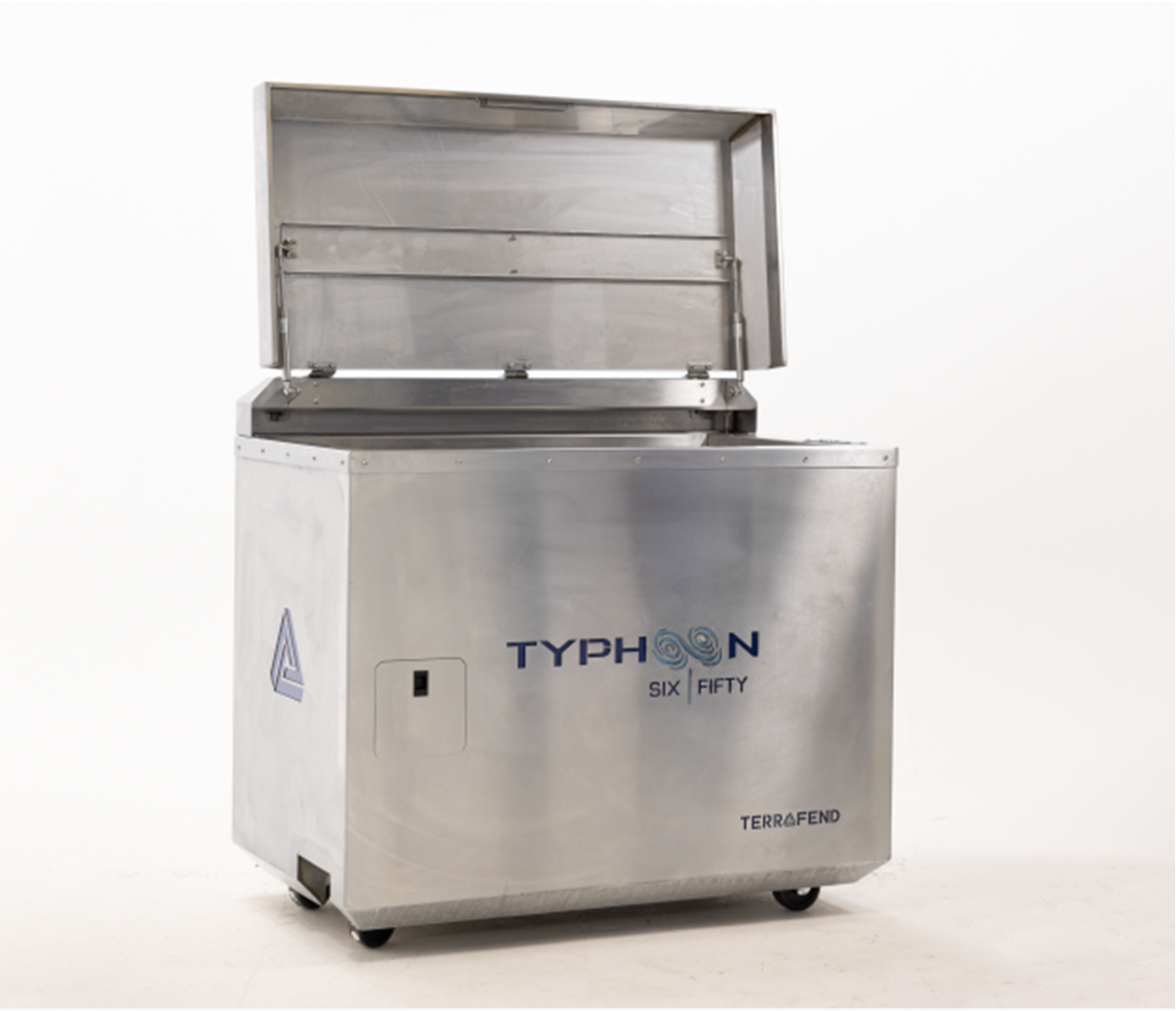

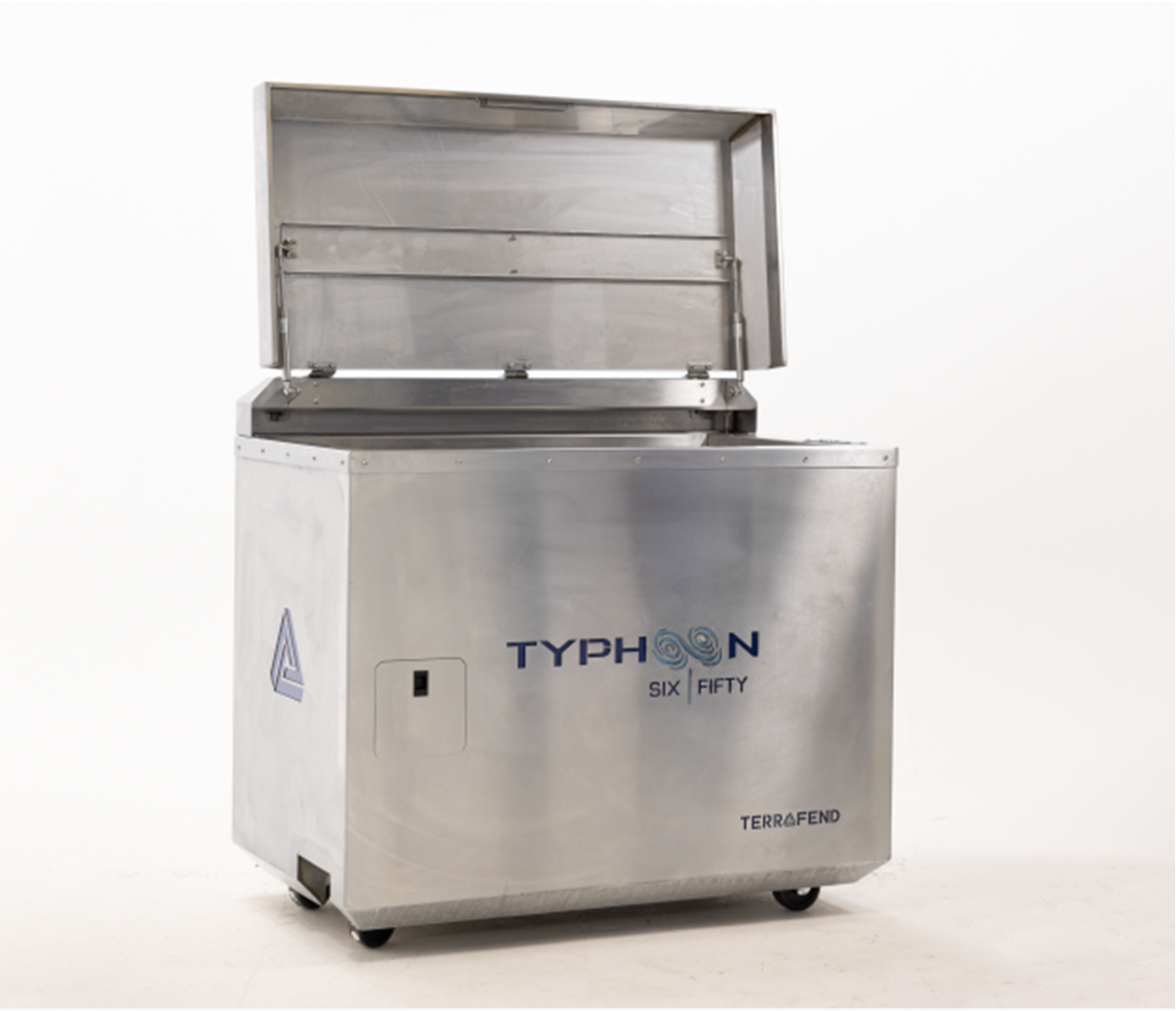

The Typhoon 650 is a heavy-duty manual wash tank designed for larger parts and demanding workshops. With a spacious cleaning area and integrated soak tank, it delivers outstanding performance with Terrafend fluids - replacing solvent wash systems with safer, smarter technology.

The Shockwave 3000 is a compact ultrasonic cleaning system delivering powerful cavitation in a smaller footprint. With a 300L tank, lift shelf, and wash gun, it works seamlessly with Terrafend fluids to remove contaminants safely, efficiently, and with precision.

The Shockwave 6000 is a large-format ultrasonic cleaning tank built for heavy industrial use. With a 600L capacity and dual transducers, it delivers exceptional cavitation performance, maximising Terrafend fluids to remove tough contaminants quickly, safely, and with proven reliability.

The Trident Pro | Jet is a high-performance aqueous blast cabinet designed for small-format precision cleaning. With adjustable pressures from 500-1500 PSI, integrated extraction, LED lighting, and user-friendly features, it delivers powerful results with Terrafend fluids across industrial applications.

The Monsoon Pro | Air is a fully enclosed spray gun cleaning system, purpose-built for gravity and suction-fed guns. Designed for use with Terrafend’s EKHO Dual Gun Wash, it delivers safer, smarter, and more effective cleaning already trusted by global OEMs.

The Abyss is Terrafend’s largest ultrasonic cleaning platform, built for heavy industrial use. Designed for 360° overspray removal from jigs and grids, it maximises EKHO chemistries to replace caustic tanks and pyrolysis with safer, more efficient, and cost-effective cleaning.

The Vortex is a large-format heated soak tank engineered for industrial overspray removal. Optimized for Terrafend’s EKHO Grid Strip, it cleans metal and plastic floor grids quickly and effectively, replacing caustic tanks and gas-heavy processes with a safer, sustainable solution.

Terrafend, in partnership with BASCA, delivers custom high-pressure cleaning systems for vessels and fixed infrastructure. Tailored to each facility and Optimized for AURA chemistries, these solutions deliver rapid, safe, and sustainable cleaning - reducing VOC exposure while transforming industrial plant performance.

– Ricky Greenwood, Group Environmental and Sustainability Specialist, Scott Bader

We’ve partnered with BASCA SRL in Italy to develop a next-generation mobile vessel washing system, designed specifically for use with our AURA chemistries. Available in both ATEX and non-ATEX formats, the system delivers our non-flammable, non-toxic and non-carcinogenic coating removal fluids at high pressure, ensuring safe, effective, and reliable cleaning.

Its compact footprint, intuitive operator interface and customizable programme functionality make it simple to set up and adapt to the unique requirements of each plant. This flexibility allows operators to achieve optimal wash cycles and consistently high-quality results with ease.

By adopting this system, you can reduce site risk, cut waste and emissions, and drive meaningful performance improvements in vessel cleaning. To discover how this technology can benefit your operations, speak to a member of our commercial team today.

FIND OUT MORE →

The Abyss and Vortex, powered by Terrafend’s advanced EKHO Jig Strip and Grid Strip solutions, are redefining paint overspray removal for OEM paint plants and industrial operations.

By moving away from outdated methods such as pyrolysis and fluidised bed cleaning, businesses can cut emissions, reduce gas consumption, and eliminate unnecessary risks, all while achieving cleaner, safer, and more consistent results. The technology also reduces jig recalibration needs, saving time and protecting infrastructure.

Already proven by leading OEMs, this platform sets a new benchmark for safety, sustainability, and cost efficiency. Contact our sales team today to find out how Terrafend can transform your cleaning process.

FIND OUT MORE →

For OEM paint plants, the Monsoon Pro | Air combined with EKHO Dual Gun Wash is setting a new standard in spray gun cleaning. Designed for gravity and suction-fed guns, it eliminates the reliance on solvent-heavy processes that expose painters to VOCs and environmental risk.

With this system, both water-based and solvent-based coatings are cleaned from spray guns faster, safer, and more consistently, reducing downtime, extending equipment life, and ensuring superior finish quality on every job. Proven efficiency makes it both a performance and safety upgrade for paint mixing rooms and booths.

By dramatically cutting VOC emissions and minimising risks to staff and infrastructure, this platform is already being adopted by leading OEMs and engineering giants. Speak to our sales team today to learn how it can revolutionize your spray operations.

FIND OUT MORE →

For merchant fleets, the NEMO range is changing how cleaning is managed at sea. Instead of relying on dozens of hazardous products, crews can now complete 80% and above of onboard cleaning tasks with just two safe, water-based solutions.

From decks and tanks to engine rooms and accommodation spaces, NEMO simplifies operations, reduces chemical risk, and delivers consistent, proven performance where it matters most. Crews benefit from safer handling and a streamlined approach to everyday cleaning and maintenance tasks.

Already trusted by fleet owners, NEMO is helping operators cut chemical storage, lower emissions, improve crew safety, and drive meaningful cost savings. Speak to our sales team today to see how NEMO can support your vessels.

FIND OUT MORE →

Are you looking for a partner that can help you transform cleaning processes and meet your sustainability objectives? Terrafend has deep experience in designing high-impact solutions for manufacturers. Our Ambimization® specialists are ready to help find your ideal solution. Fill out the form to request a conversation.